News

Ground conditions

Ground hazards include:

• Sloping ground – Never ignore tilt alarms and always know your machines capacities and limitation. Check the data plate, decals or operator manual

• Underground services – check for signage or site plans, use locators or pot holing, contact Dial before you dig (1100 or 1100.com.au)

• Soft or unsupported ground – talk to a qualified engineer to get an engineer’s report. Relocate to better ground, use more packing (steel plates, timber, plastic pads or other suitable products to spread the weight over a larger area. Use pig sty – 90 degree stacking for each layer of packing)

• Uneven ground – drive equipment with booms lowered and retracted and at slow speeds

• Trenches – use the 1 metre away for every 1 metre deep rule. Further distances away for unstable ground

• Slippery – clean up spills, use alternate routes

• Obstacles – remove or find alternate routes

How to avoid stabilisers, outriggers or wheels sinking into the ground:

· Assess the ground conditions before setting up. Talk to a suitably qualified engineer or other competent person to assess the load bearing capacity of the surface. Otherwise get an engineer’s report that specifies this

· Where possible, relocate the plant to the best ground to set up on

· Use suitable packing such as hardwood timber, steel plates or plastic pads

· With trenches use the 1 metre away for every 1 metre deep rule. Even further if it is soft or waterlogged

· Level out plant where outriggers or stabilisers are fitted

· Stay within the plants operating capabilities. Pushing the limits is a common cause of tip overs or plant damage

· Try to avoid setting up near underground services. Dial before you dig (1100 or 1100.com.au), review site plans or look for signs of underground services

· Don’t setup near storm water drains or grates. If you have to, use additional packing

· Always check for changing conditions. Identify hazards before you start work and constantly throughout the day. Put risk control measures in place before starting work and as new hazards arise. Don’t get complacent, constantly check for changing conditions.

There is a cautionary tale video of a crane collapse

More information is available by calling 0410019149 or emailing enquiries@flts.net.au

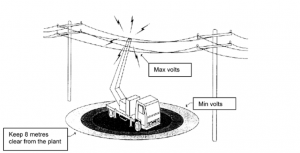

Contacting Power Lines

Avoiding Over Priced And Substandard Training

Are you tired of dealing with training organisations who?

- Don’t deliver what they promise

- Don’t understand your business and what you need

- Are unwilling or unable to tailor the training to meet your needs

- Use trainers are boring, inexperienced and lack the knowledge they should have

- Take your workers away from the job for longer than should take

Why not try us? We:

- Care about our customers

- Work to deliver the best outcomes at affordable prices with minimum down time for your workers

- Employ experienced and passionate trainers

We offer training in:

- EWP Yellow Card

- Telehandler Gold Card

- Heights safety

- Confined Space

- Emergency response and firefighting

- LVR/CRP

- Verification of Competency

- Refresher Training

- Other training tailored to your needs